Your new post is loading...

Your new post is loading...

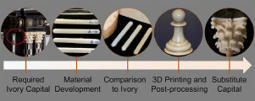

"Through history, numerous art, religious and every-day objects were carved from ivory because of its aesthetic appearance, convenient workability and its durability. Since the ivory trading ban was passed in 1989, many natural and synthetic materials were introduced as a replacement, but these are typically only available in bulk. …The newly developed substitute material called "Digory" is processible with an additive manufacturing technique that derived from stereolithography."

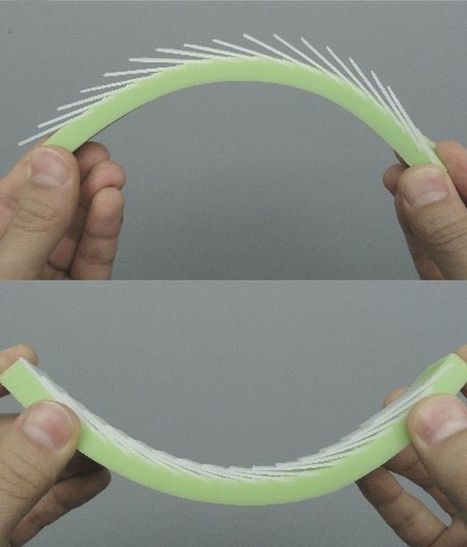

"A team of scientists at the Wyss Institute for Biologically Inspired Engineering at Harvard University and the Harvard John A. Paulson School of Engineering and Applied Sciences has evolved their microscale 3D printing technology to the fourth dimension, time. Inspired by natural structures like plants, which respond and change their form over time according to environmental stimuli, the team has unveiled 4D-printed hydrogel composite structures that change shape upon immersion in water."

"Additive manufacturing shows great promise for making things in a way that more closely resembles natural form, but some of the below strategies are worth investigating to reduce or eliminate toxicity and to make more functional products.".

A new developed approach to 3D printing has produced an octopus-inspired robotic device claimed to offer an unprecedented level of agility. Engineers crafted the artificial muscle using commercially available material and say it points to a future of advanced robotic devices inspired by nature.

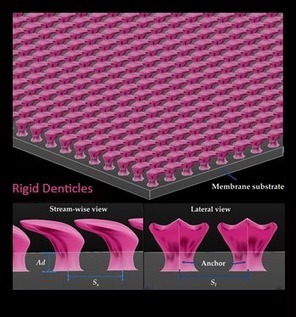

"Scientists have been trying to unlock the secrets of shark skin for more than 50 years. The key to sharks' hydrodynamic prowess lies in how the rigid, tooth-like structures that coat their flexible skin change the flow of water as sharks swim forward – but attempts to quantify this effect have fallen short. After all, it's tough to fabricate a material that closely mimics shark skin, a marvel of Nature honed over the 400 million years that sharks have sleuthed the seas."

"Another incredible adaptive animal and insect feature is the development of protective scales that provide insulation, and serve as a camouflage to ward off predators. In fact, animal scale functioning is so impressive that recently “dermal modification” — or the adaptive properties of animal skins — has inspired the scientific development of human armor using 3D printing."

"Making curved shapes on a 3D printer often involves laying down support material which has to be cut away and disposed of at the end. Printing the support material adds to the cost, slows the process down, generates waste and results in additional work to finish the component where the support has been cut away. The DPG team decided to investigate ways of developing self-supporting printed structures as part of a continuing project to design and develop a fixed wing Unmanned Aerial Vehicle, or UAV. Designers used fractal mathematics, which generates repeating patterns, to create an intricate internal structure for the wing, resembling that of an insect, where repeating patterns of veins strengthen the wing, while allowing its surface to remain flexible." Photo details: "Ischnura senegalensis October 2007" by Laitche. Licensed under Public Domain via Wikimedia Commons.

"Octopuses and squid are amazing animals. Their unique attributes have already inspired invisibility cloak technology and more comfortable medical implants. Now, their ability to flee quickly from predators has inspired a new propulsion system for boats and other water craft."

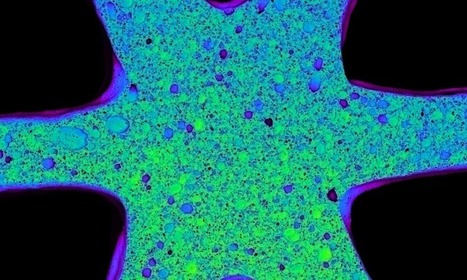

"Researchers at MIT have developed an approach that allows them to create physical sample of a multiscale computer model of a synthetic material. he approach allows creation of complex hierarchical patterns such as bones. The process could be scaled up to provide a cost-effective way to manufacture composite materials that are tailored for specific functions in different parts of a structure."

|

"Nature does amazing things with limited design materials. Grass, for example, can support its own weight, resist strong wind loads, and recover after being compressed. The plant's hardiness comes from a combination of its hollow, tubular macrostructure and porous microstructure. These architectural features work together to give grass its robust mechanical properties. Inspired by natural cellular structures, researchers at the Harvard John A. Paulson School of Engineering and Applied Sciences (SEAS), the Wyss Institute for Biologically Inspired Engineering at Harvard University, and MIT have developed a new method to 3D print materials with independently tunable macro-and microscale porosity using a ceramic foam ink."

Researchers at the University of California, Riverside and Purdue University have used the mantis shrimp as inspiration for a new 3D printed material. The crustacean’s club-like appendage, used to beat prey, consists of an unusual herringbone pattern, which the researchers synthetically replicated.

"Airbus and its subsidiary APWorks, in collaboration with Autodesk-owned architecture firm The Living, has started 3D printing the world’s largest metal 3D printed airplane part. The jet partition, 3D printed in a high-tech alloy called “Scalmalloy”, is 45% lighter than current partitions. [...] To create the most durable and lightweight design possible, the project team sought inspiration from nature. Bionics, which involves examining natural mechanics to see how they could be mimicked in technological devices, has been crucial in the production of the 3D printed component. The jet partition was created with custom algorithms, which generated a design that mimics cellular structure and bone growth. Airbus has also been exploring weight-saving aircraft structures based on the construction of super-strong water lilies, and torsion springs based on fish jaws."

Crowdsourced innovation service Innonatives has posted a challenge seeking “radical ideas” on how to combine biomimetics and 3D printing for sustainability. Innonatives is a platform where any company may post a significant challenge and seek the public’s assistance in solving the issue. In this case, the partnership of Biomimetics Hessen and the Association of German Industrial Designers (VDID) are posting a major challenge. They invite the community to:

«Present Their most brilliant and radical ideas on how Both techniques (Biomimetics and 3D Printing) can be used in combination to generate radical improvements towards environmental, social and economic sustainability». It’s not clear when the challenge closes, but the ten best ideas as determined by an “expert jury” will be presented in a special event on 15 October in Germany."

"As additive manufacturing, or 3D printing, becomes more and more sophisticated and capable of direct production in some applications, a class of software is emerging that exploits the capability of AM technology to produce objects in a highly freeform manner. Engineering and manufacturing software giant Autodesk refers to this emerging model as goal-directed design (GDD). Autodesk is building a GDD CAD system called Dreamcatcher, now under development at its research lab while deployed in beta form to a number of the firm's customers.[...] Rather than defining a part in great detail from the top down, in bio-inspired computer-aided design, the user gives the software a set of fundamental rules and lets it seek out the optimal solution to a problem. Autodesk’s GDD system turns CAD on its head in a similar way; as opposed to a starting point of inputting the desired geometry, Dreamcatcher's bio-inspired algorithms generate the optimal design solution, employing whatever geometry solves the problem."

"Inside a bud, a flower’s petals lie in wait, a tight bundle of compressed tissue. When the conditions are right, they burst forth, blooming in an impressive display of geometry and color. During this opening period, which may last as long as 7 days or be as brief as 5 minutes, the cells that make up the petals may expand to 20 to 50 times their initial length. This great and relatively sudden inflation accounts for most of the flower’s shape. Some cells within the petal grow more than others and this differential growth is responsible for the 3D form of the petals. [...] Multi-material 3D printing may give us a way to incorporate such movements into the architecture of products and buildings. The provocatively named discipline of 4D-printing explores fabricating shape changing materials by means of 3D-printing. The differential growth of flowers suggests a way of designing such shape changing products."

"For her graduation project at the Royal Academy of Art, The Hague, industrial designer Lilian van Daal developed a concept 3D-printed soft chair called Biomimicry... [...] Van Daal looked for ways to create a soft chair from one type of material and retain the basic features required for the item to function as a chair. The chair needed to be firm and rigid in some areas and soft in other areas, and Van Daal experimented with various geometric structures to come up with a structure suitable for her design concept. The designer used nature as inspiration and studied the structure of plant cells – whose structural design allows them to perform different functions."

"Researchers working to design new materials that are durable, lightweight and environmentally sustainable are increasingly looking to natural composites, such as bone, for inspiration: Bone is strong and tough because its two constituent materials, soft collagen protein and stiff hydroxyapatite mineral, are arranged in complex hierarchical patterns that change at every scale of the composite, from the micro up to the macro."

MIT researchers headed by Mediated Matter Group founder Neri Oxman to 3D print a pavilion by imitating silkworms.

|

Your new post is loading...

Your new post is loading...